Products

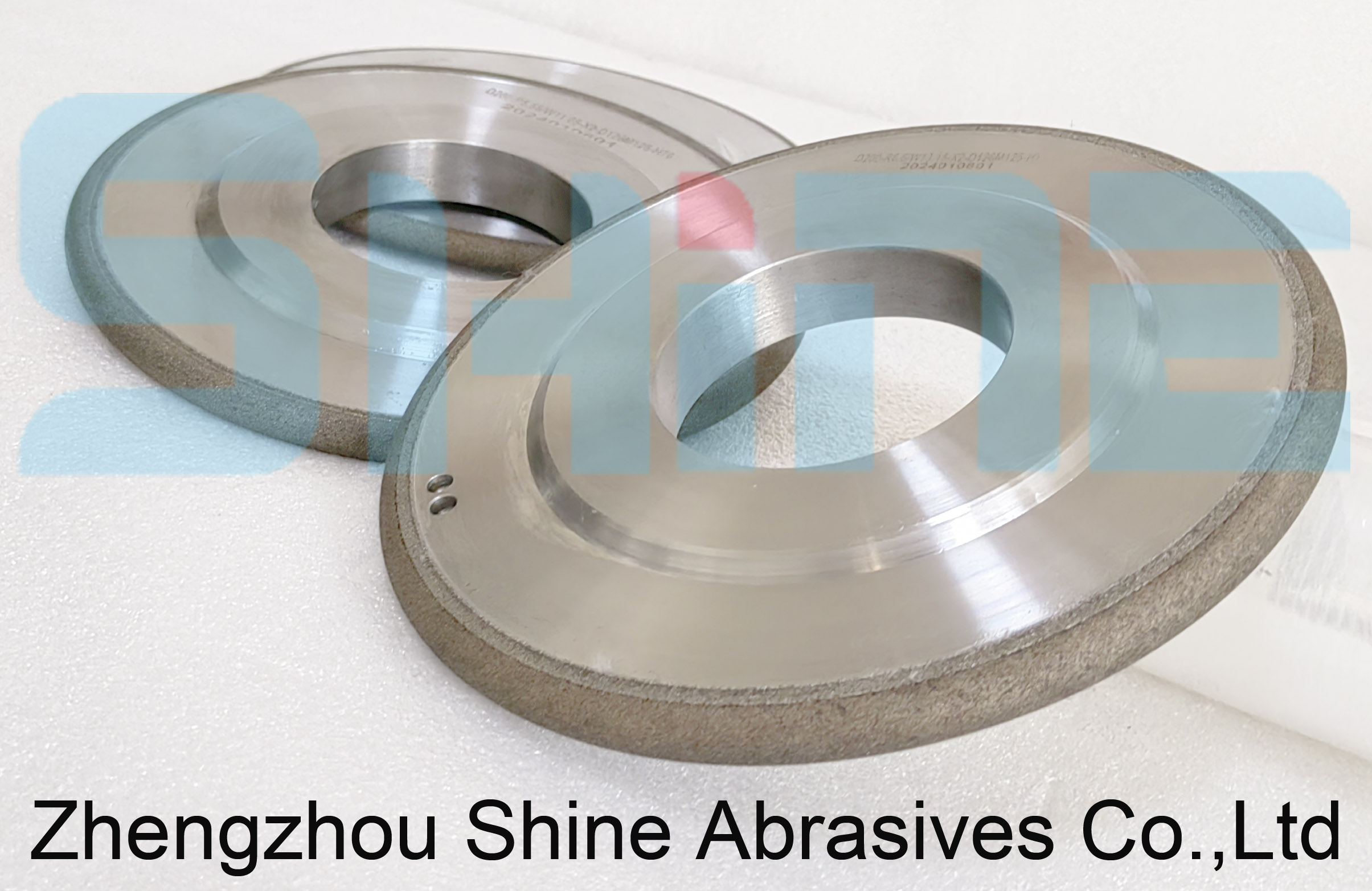

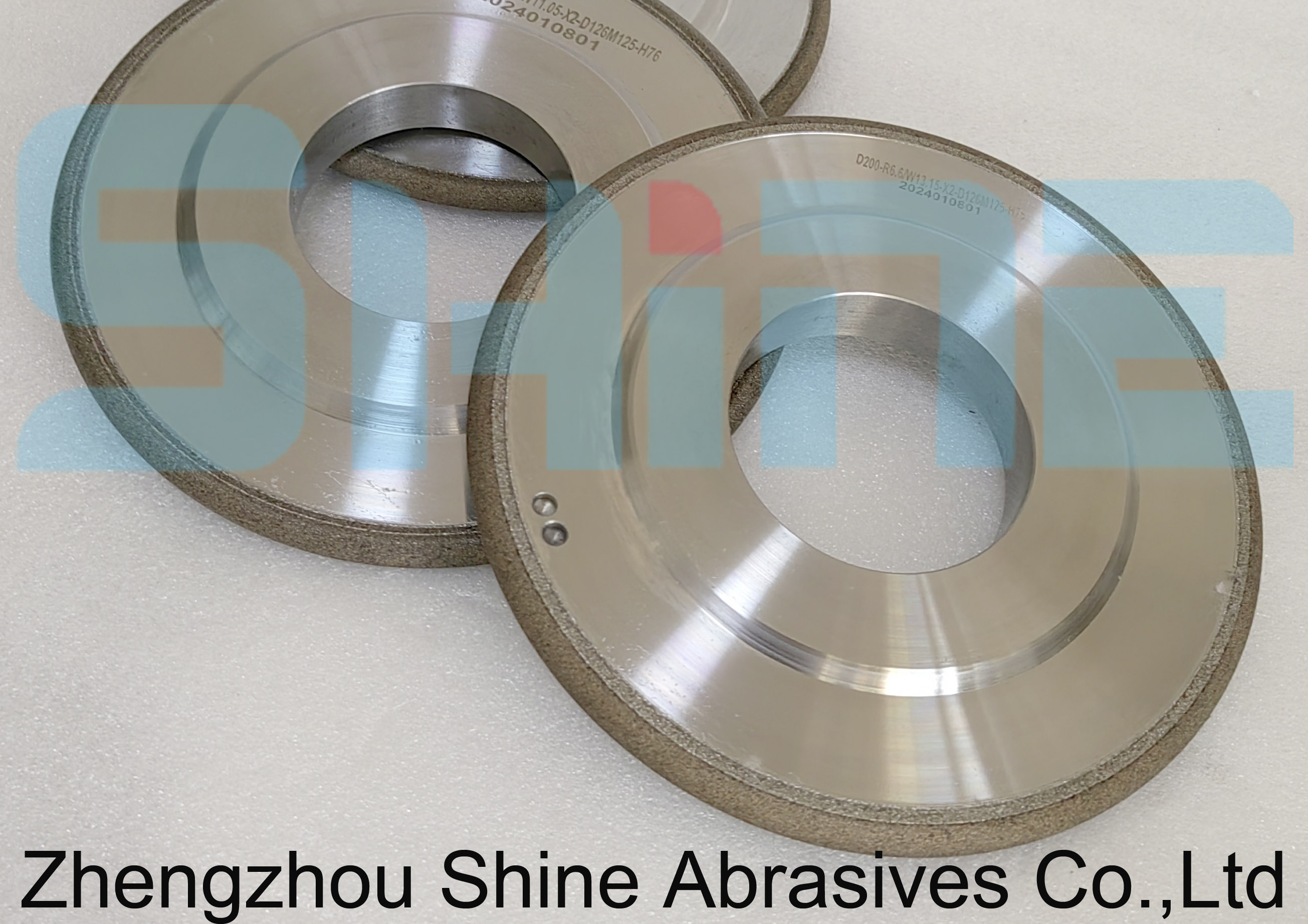

- Resin Bond Diamond Wheels (19)

- 1A1 Diamond Wheels (9)

- CBN Sharpening Wheel (18)

- Centerless Grinding Wheels (4)

- 1A1R Diamond Wheels (5)

- Electroplated Diamond Wheels (6)

- Electroplated Diamond Tools (6)

- Metal Bond Grinding Wheels (14)

- PCBN Tools (8)

- CNC Grinding Wheels (4)

- Vitrified Bond Wheels (7)

- Diamond Dressing Tools (7)

Contact Us

Tel:+86371-67129055 Mr Li: 15003895611

Fax:+86371-67129055

Email:shineabrasives@vip.163.com

News

Grinding conditions affect grinding wheel clogging

1. Grinding wheel linear speed

Increasing the linear speed of the grinding wheel will reduce the maximum depth of cut of the abrasive grains and the chip cross-sectional area. At the same time, the number of cutting times and grinding heat will increase, which will increase the amount of clogging. When grinding, the grinding wheel speed should be selected appropriately.

2. Workpiece speed

Practice has proven that doubling the working speed will triple the amount of grinding wheel clogging. Because the higher the speed of the workpiece, the greater the load on the abrasive grains, the shallower the cutting depth of the abrasive grains, and the smaller the chip cross-sectional area. When the grinding thickness increases, the passivation of the abrasive grains increases, which increases the extrusion of the grinding layer of the workpiece by the grinding wheel. , which is equivalent to the hardening of the grinding wheel properties, which will aggravate the clogging of the grinding wheel.

3. Grinding method

In terms of grinding methods, increasing the contact area between the grinding wheel and the workpiece will aggravate the clogging of the grinding wheel. Due to the large contact area between the grinding wheel and the workpiece, it is difficult for the coolant to enter the grinding area. The grinding heat is large and the temperature is high, creating conditions for clogging, which can easily lead to chemical adhesion clogging and embedded clogging. For example, end grinding is more likely to be clogged than circumferential grinding, and transverse plunge grinding is more clogged than longitudinal grinding.

4. Radial cutting amount

The influence of radial cutting amount on grinding wheel clogging shows a hump trend. When the radial cutting amount ap<0.01mm, clogging occurs. When the cutting amount increases to ap=0.03mm, the blocking amount shows a decreasing trend. When the cutting amount continues to increase ap=0.04mm, the blocking amount rises sharply.